CUTTING BOTTLE

- Capacity 50 CuFt- 1000 CuFt

- All steel welded construction from SA 36/SA 516 GR 70/eqvt.

- Aeration jet system

- Burried /Above Ground type with Hopper outside

- Fill, vent and discharge lines are easily accessible

- Certification :-U Stamp (On request)

- Lifting lugs are MPI tested & Certified for empty lift

- Hydro fill tested to suit design standard

- External grit blasted to SA 2.5 & epoxy paint system

Options:

Twin Cutting Bottle-Capacity 2x 50 CuFt

Special design and equipment on request

BARITE BULKERS

- Capacity 14cbm (500cuft).

- Material of construction A36/ 516gr70.

- Working pressure 30psig.

- With Fill, vent, discharge and air line.

- Axle 2x16T

- Tyres 12R24 with Trilex type rim.

- With Hermanns aeration system.

- With Diesel engine driven Compressor.

CENTRIFUGAL PUMP SKID

- Material of construction A36.

- Centrifugal pump skids of size 5x6x11 and 10x12x23

- Fitted with diesel engine.

- With C pump operated by PTO.

- With Control panel

- With diesel tank

- With required pipe fittings and connections.

- With drip plate at the bottom.

- With fork lift pockets and working lights.

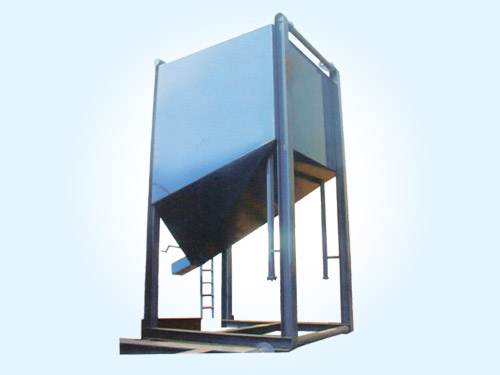

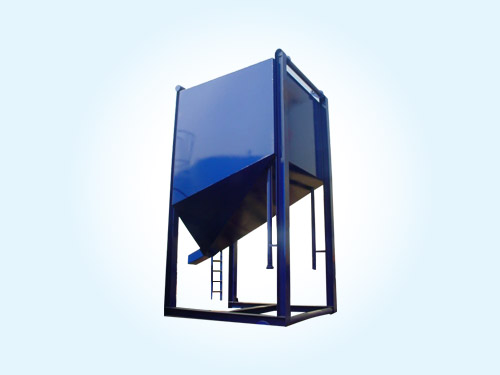

GRAVITY SILO

Square Tank

- Capacity 400-1200 Cuft.

- All Steel welded construction from SA 36/ eqvt steel plates.

- Lift frame.

- Gravity discharge.

- With DNV 2.7-1 certification for frame if required.

- Provision for mounting compression load cell.

- Fabricated gate valve with rack & pinion or Pneumatic.

- External grit blasted to SA 2.5 & epoxy paint system

Options:

Round tank - 1200CuFt.

Special design and equipment on request.