Our state of the art engineering and fabrication facilities extend over 29,000 square meter of covered space and 56000 square meter of total area in Al Quoz Industrial area, a new 35,000 square meter facility in a total area of 90,000 square meter area in Dubai Industrial city and a 3300 square meter satellite mounting plan in Ghala, Muscat, Oman.

Our infrastructure facilities include:

- Roundo – plate rolling machine

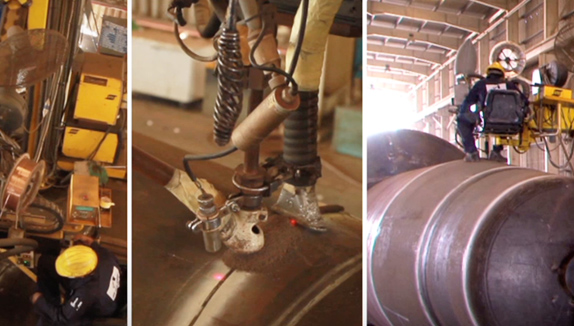

- Automatic Submerged Arc Welding Machines

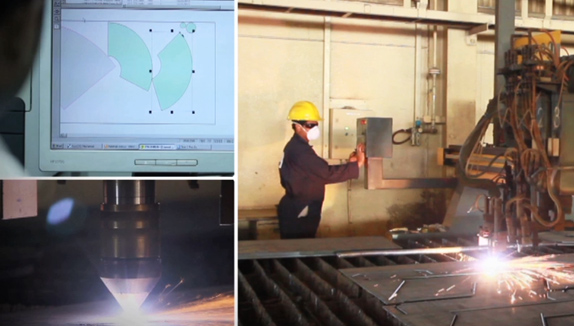

- CNC Oxy- Acetylene plate cutting machine

- Hydraulically operated plate blending machine

- NC controlled Hydraulic Press brake

- NC controlled Hydraulic Shearing Machine

- NC controlled Flanging Machine

- Air Jet Plasma cutting machines

- Welding Rectifiers 400 A capacity

- MIG/TIG & Wire Feeder (FCAW) welding machines

- Radial Drilling Machines

- Mobile lifting capacities 4 tons to 35 tons

- Overhead crane capacities 5 tons to 20 tons

- Blasting facilities

- Airless spray painting facility with water curtains

- Dish end manufacturing

- Automatic submerged arc welding machines

- State of the art CSC test rig to test and certify 20ft, 40ft and 45ft container size structures

- Latest cutting, bending and rolling faculties

Experienced project management professionals, detailed technical knowledge of management disciplines such as contracts, risk management and cost estimation, broad awareness of industry and customer drivers, experienced shop and supervisory personnel - In all of our activities we have a successful track record of reducing project costs, improving schedules, managing risks, maximizing safety and meeting key objectives. And what sets us apart is our commitment to seeing each project through its successful completion.

Engineering Capabilities

- Al Shirawi Equipment has an experienced engineering & designing team for providing all engineering solutions to Customers as per the International Engineering Codes & standards (ASME, API, DNV 2.7-1, 2.7-3 & DNV-OS-E101etc.)

- We use the latest Software to meet Customer requirements:

- 3D modeling – Software: CADWORX & SolidWorks, in addition to Autodesk Inventor.

- Complete solution for Pressure Vessel - Design, Analysis, and Evaluation- Software: PV Elite

- ASME Vessels and Piping components - Finite Element Analysis (FEA) - Software: Nozzle Pro

- Structural Skid Analysis - Software: Staad-Pro.