Well Services

Well Services & Completion

Our manufacturing facility specializes in a complete manufacturing line starting from raw material to fabrication, then to assembly and paint.

With years of experience, we have product design experts supported by a staff of engineers and design detailers available to assist with any manufacturing requirements. Our engineering and design team used the most advanced software to design, analyze, and produce manufacturing drawings.

At Al Shirawi Equipment Company, we design, develop, test and manufacture new equipment and products to address our customers’ drilling and completion challenges. We offer a wide range of essential oilfield equipment and services, a full range of high-quality standard parts and products and can also develop customized solutions for specific customer needs. Our manufacturing capabilities enable us to deliver the most cost-effective and reliable products in the shortest possible cycle times.

Pressure Vessel, Heat Exchangers, Storage Tanks etc

Silos - Pressure & Gravity.

Batch mixers

Cutting bottles, Weigh batch blenders etc for cementing operations.

Dust Collector.

Semi Trailer -Banana, Acid Tank & Tripod.

Skid mounted storage tanks (Acid, Water, Slurry, Fuel).

Acid Transportation Tank (with crash frame)

Frac tanks

Degassers

Mud-Gas Separators.

Our manufacturing facility specializes in a complete manufacturing line starting from raw material to fabrication, then to assembly and paint. With years of experience, we have product design experts supported by a staff of engineers and design detailers available to...

Read moreCementing Equipments

Fracturing Equipments

Coil Tubing

Cementing Equipments

Cutting Bottle

Options:

Twin Cutting Bottle-Capacity 2x 50 CuFt

Special design and equipment on request

Barite Bulkers

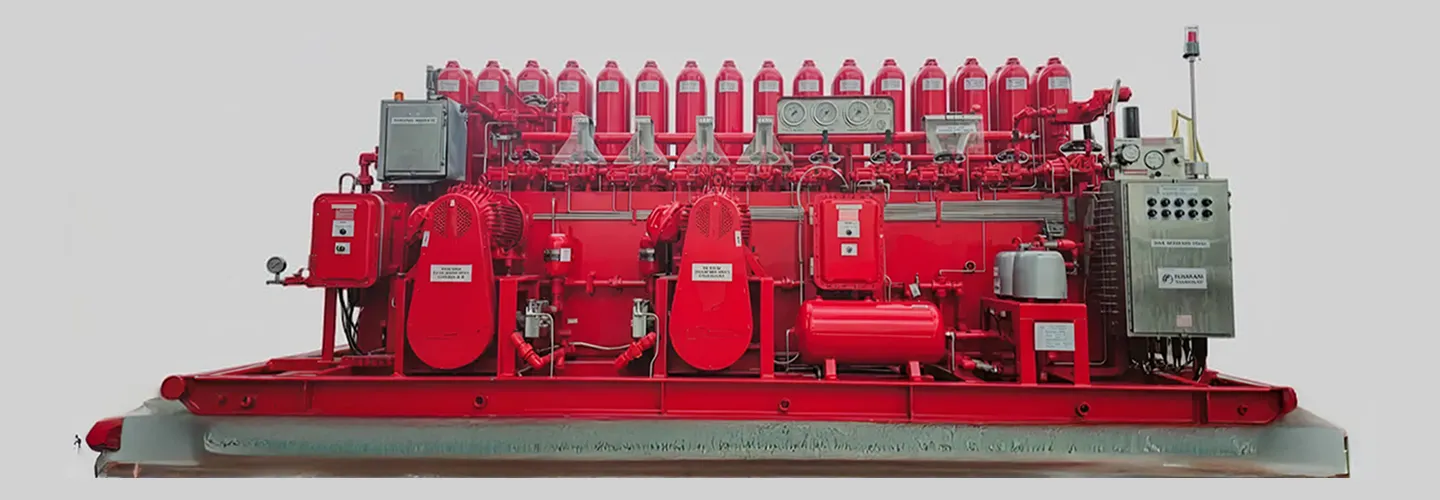

Centrifugal Pump Skid

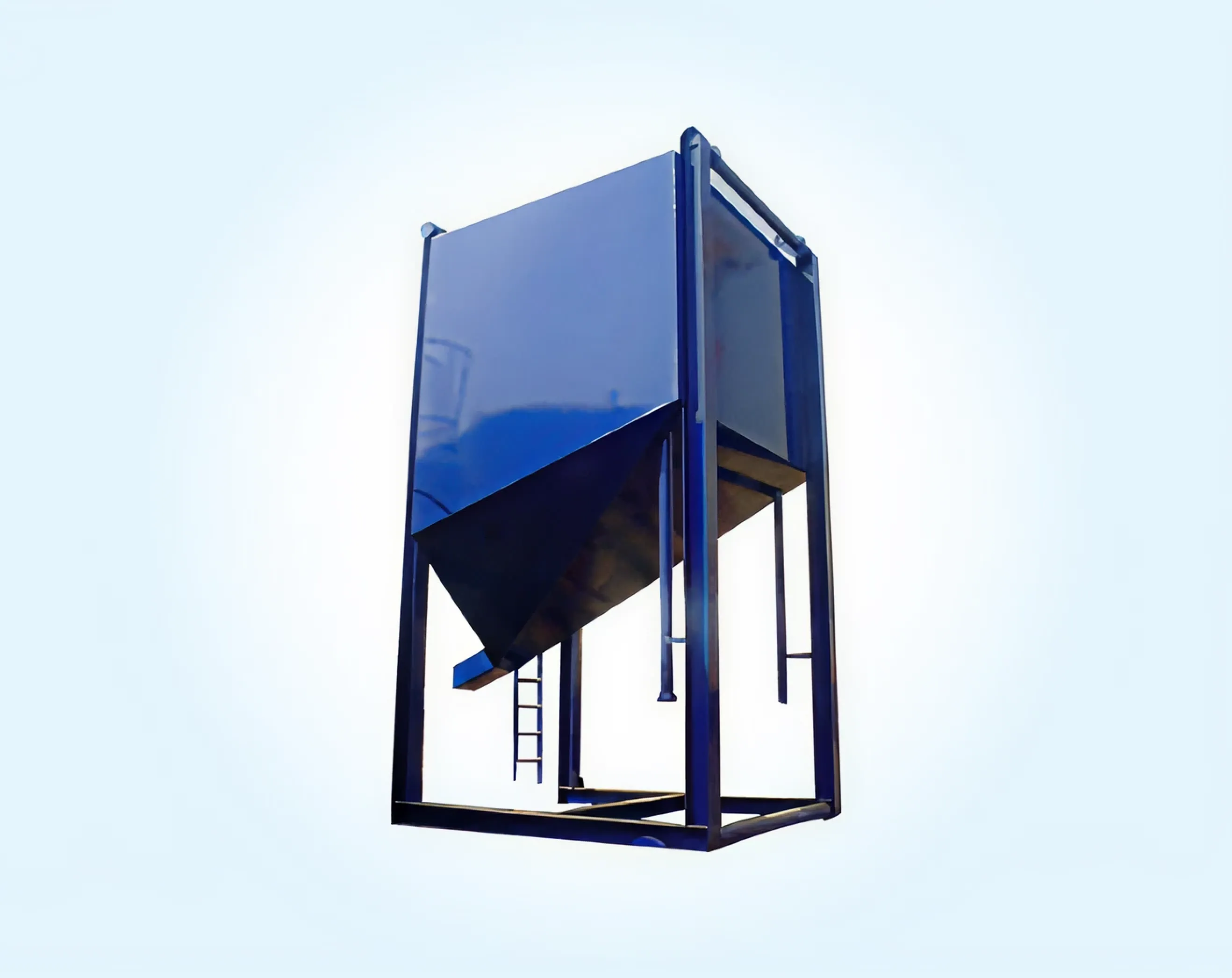

Gravity Silo ( Square Tank )

Options :

Round tank - 1200CuFt.

Special design and equipment on request.

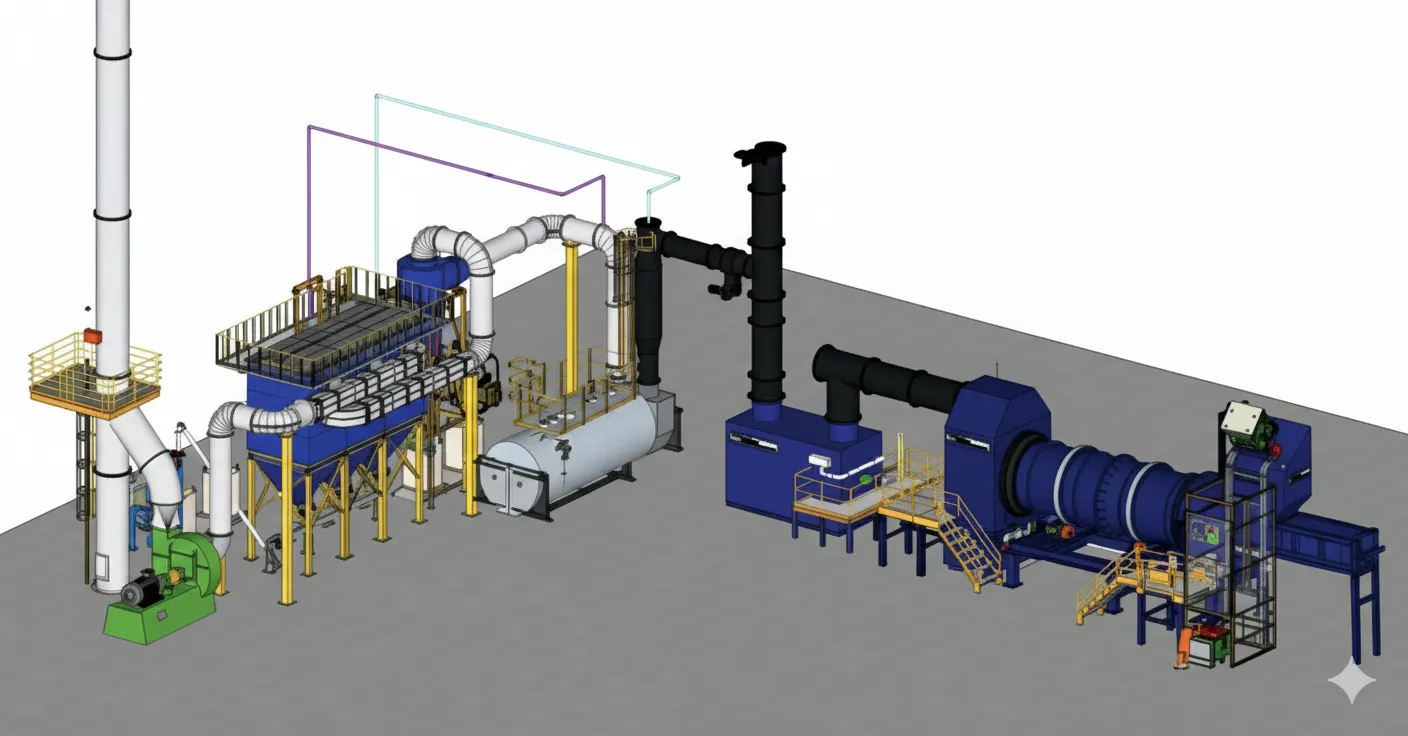

Dust Collector

Options:

Special design and equipment on request.

Weigh Batch Blender

Options:

Special design and equipment on request

Surgetank

Batch Mixer

Options:

Valves- Manual /Actuator controlled

Special design and equipment on request

Banana Bulker

Options:

Provision for dual and triple compartment. (On request)

Provision for surge tank at the rear side of trailer(On request)

Diesel engine & compressor fitted basesd on customer's advice

Special design and equipment on reqest.

Tripod Bulker

Options:

Dual pod (Bipod) semi trailer – 2 x 450 CuFt / Quadrapod 4x400cuft

Special design and equipment on request

Cement / Barite Silo

There are different types of cement silos which generally come equipped with an electronic weighing system with digital display and printer. This allows any quantity of cement or powder discharged from the silo to be controlled and also provides an accurate indication of what remains inside the cement silo. The Cement Silo along with the Weigh Batch Blender is designed to mix cement, bentonite, barite, liquid additives, etc. for oilfield use. One of our USP’s is that based on our clients’ needs we provide cement silos depending on the bulk plant requirement.

General Specifications:

Options:

Twin Silo- Capacity 2 x 1000 Cu Ft

Provision for manholes at top on request

Special design and equipment on request

Fracturing Equipments

Fracturing is a well stimulation method in which rock is fractured by a pressurized liquid. The process includes the high-pressure injection of 'fracking fluid' (mainly water, covering sand or other proppants suspended with the aid of thickening agents) into a wellbore to create cracks in the deep-rock formations through which natural gas, petroleum, and brine will flow more freely. ASECO’s success is built on over 40 years of rich history. Our extensive experience, combined with our broad competencies of our specialists, infrastructure and facilities has allowed ASECO to be a reliable name across the most demanding oil & gas, petrochemical and other industries across the globe.

Keeping in mind that different environments and road protocols need different designs, ASECO fracturing equipment is accessible in truck, frac semi trailer, acid tank trailer, and skid mounted designs. Several designs for different types of units are available and if the end users are looking for customization, our veteran in-house engineering team will make sure that this design will also be comprehended.

Some of the fracturing equipment that we have are acid tank trailer, acid storage tanks, frac tank semi trailer, acid transporting tank with crash frame. Fracturing equipment is worked across a range of different pressures and injection rates. On the high end of the gamut, the pressure used for fracking may as high as 15,000 psi and the injection rate could be as much as 100 barrels per minutes.

Fracturing is a well stimulation method in which rock is fractured by a pressurized liquid. The process includes the high-pressure injection of 'fracking fluid' (mainly water, covering sand or other proppants suspended with the aid of thickening agents) into a...

Read moreFracturing Equipments

Acid Transporter

Options:

Type : Horizontal / Vertical

Special design and equipment on request.

Acid Storage Tank

Accumulating years of experience, our product design experts supported by a staff of engineers and design detailers are available to assist with any manufacturing requirements. Our engineering and design team use the most cutting-edge software to design, analyze, and produce manufacturing drawings. One of our products is Acid Storage Tank. One of our USP’s is that based on our clients needs we provide multi compartments and DNV 2.7-1 certification if required.

Acid trailer manufacturers and storage tanks are a part of our broader division that consist of all sorts of fracturing equipment.

Options:

Provision for multi compartments

DNV 2.7-1 certification with skid frame mounted storage tanks on request

Internal lining as per clients’ choice

Special design & DNV equipment manufacture on request

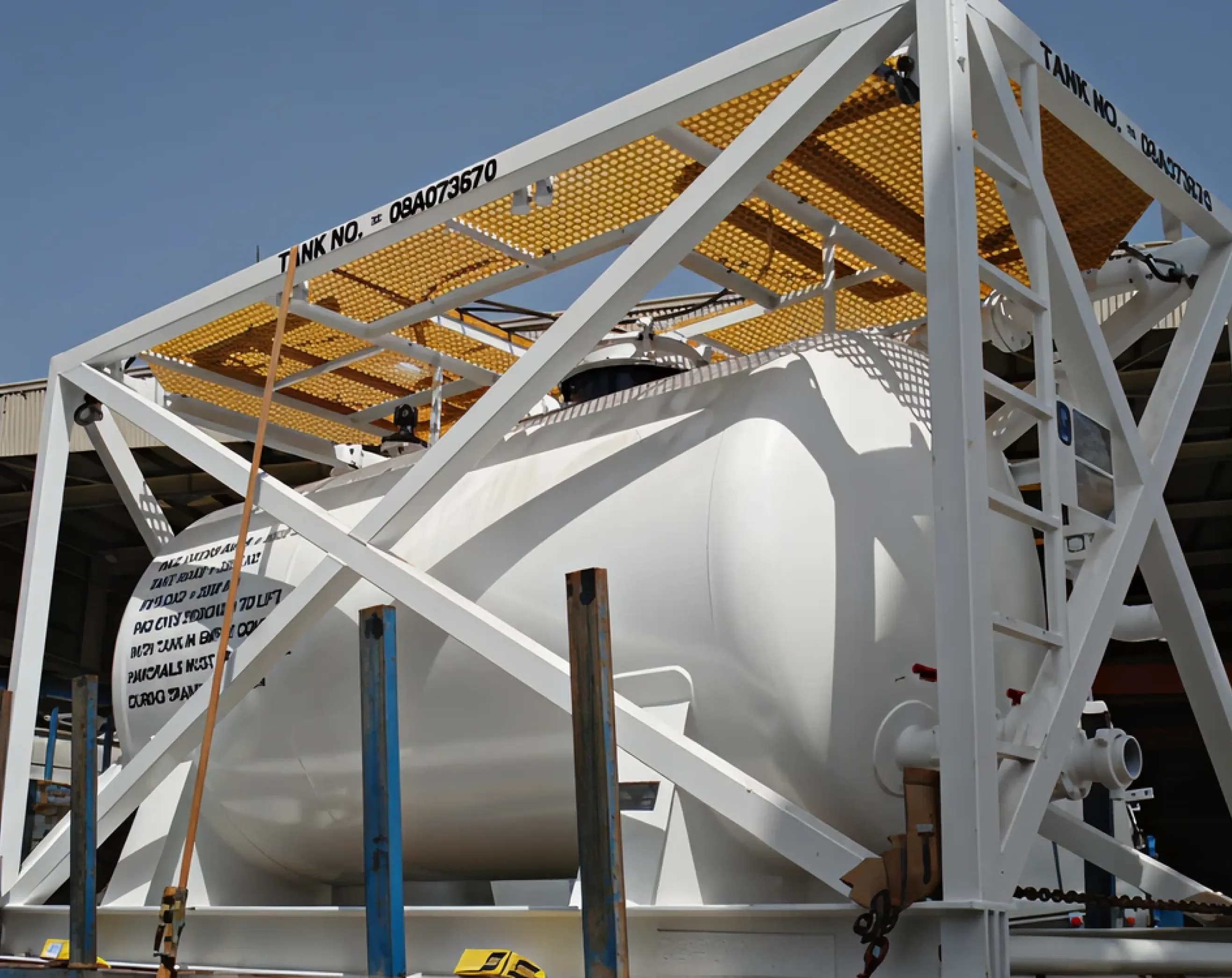

Acid Transporting Tank With Crash Frame

Options:

Type : Horizontal / Vertical

Special design and equipment on request.

Frac Tank Semi Trailer

Options :

Provision for Multi compartments

Special design and equipment on request

Coil Tubing

At ASECO, we design, develop, test and manufacture new equipment and products to address our customers drilling and completion challenges. We offer a wide range of indispensable oilfield equipment and services, a full range of high-quality standard parts and products and can also develop tailored solutions for specific customer needs. Our manufacturing competencies enable us to deliver the most lucrative and steadfast products in the shortest possible cycle times. We specialize in fabrication based on customer design. With our resilient business approach, we have adapted to the most recent evolutions to become one of the leading engineering specialists to offer complete solutions and execute complex projects.

Coil tubing supply and manufacturing comes under our division of Well Services and Completion. Coil Tubing Semi Trailer with capacity of 40-88 tons and with tires suitable to your application can also be specially designed with equipment manufactured on request.

Coiled tubing can be very effective in certain situations. Its application is increasing as experience outlines what it takes to be successful. GCC refion is a quintessential example of witnessing that rapid change that follows this technology.

At ASECO, we design, develop, test and manufacture new equipment and products to address our customers drilling and completion challenges. We offer a wide range of indispensable oilfield equipment and services, a full range of high-quality standard parts and products...

Read moreCoil Tubing

Coil Tubing Semi Trailer

Options:

Special design and equipment on request

Acid / Water Storage Tanks (Skid Mounted)

Accumulating years of experience, our product design experts supported by a staff of engineers and design detailers are available to assist with any manufacturing requirements. Our engineering and design team use the most cutting-edge software to design, analyze, and produce manufacturing drawings. One of our products is Acid/Water Storage Tank which are skid mounted. One of our USP’s is that based on our customers needs we provide skid/saddle mounted water/acid storage tank, special design and equipment manufacturers are taken on request. Understanding that different environments and road regulations require different designs and specifications to meet client requirement.

Acid and Water storage tanks are a part of our broader division that consist of all sorts of fracturing equipment.

Options:

Saddle mounted storage tank.

Capacity: 3000usg – 5000usg with or w/o internal Coating.

Internal lining as per client's choice.

Special design and equipment on request.

Contact For More Details

Explore top-tier machinery for construction, manufacturing, and more. Our experts will help you find the perfect fit.